Inside Luxpower: Our CEO's journey to Shenzen, China

Innovation at the Heart of Solar Energy

Our CEO visit began in Luxpower’s R&D department, where a team of brilliant engineers tests new ideas and prototypes. Flora, our designated guide, showed him how they use advanced modeling and simulations to optimize performance and ensure durability under various environmental conditions. It was fascinating to see how Luxpower’s relentless innovation allows them to stay ahead of the curve in the fast-evolving solar industry.

From Concept to Reality: The Production Line

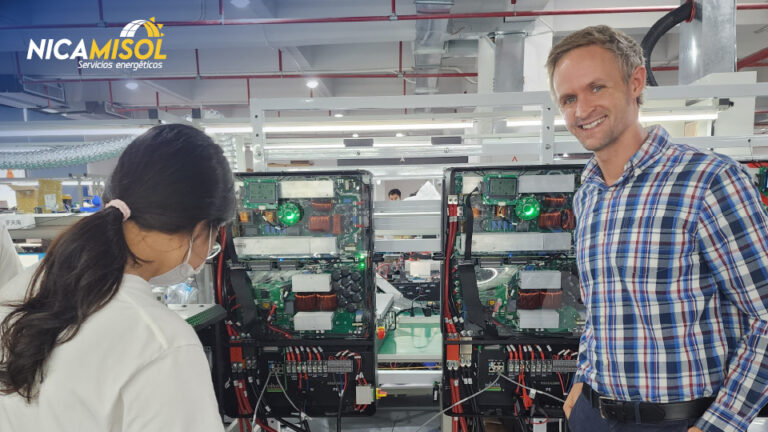

Next, Jonas explored Luxpower’s production facility, where designs are transformed into high-performance solar inverters. The first production line revealed the precision and care with which each component, including the smart card crucial for energy efficiency, is manufactured. The combination of automation and skilled craftsmanship ensures that every inverter meets strict quality standards.

Rigorous Testing: The Vacuum-Sealed Chamber

One of the most impressive parts of the tour was the vacuum-sealed chamber, where Luxpower tests their most powerful inverters under extreme conditions. From temperature fluctuations to high-pressure environments, this testing ensures that Luxpower inverters will perform reliably in any situation, providing long-lasting value to customers.

A Shared Vision: Towards a Greener Future

Luxpower’s mission, “Towards Carbon Neutrality in 2060, Greening Our Future,” reflects their commitment to sustainability. By offering advanced solutions for farms, businesses, off-grid power, and smart homes, they’re contributing to a cleaner, more sustainable energy future. This vision aligns with Nicamisol’s own goals of helping customers reduce their carbon footprint and make the shift to renewable energy.